-

Product center

-

Dynamic fatigue testing machine

-

Electronic universal testing machine

-

Electro-hydraulic servo universal testing machine

-

Automated test scheme

-

Pendulum impact testing machine

-

Drop hammer impact testing machine

-

High temperature creep endurance testing machine

-

Horizontal testing machine

-

Special testing machine

-

Standard machine

-

Spring testing machine

-

Electric insulator testing machine

-

Fastener testing machine

-

-

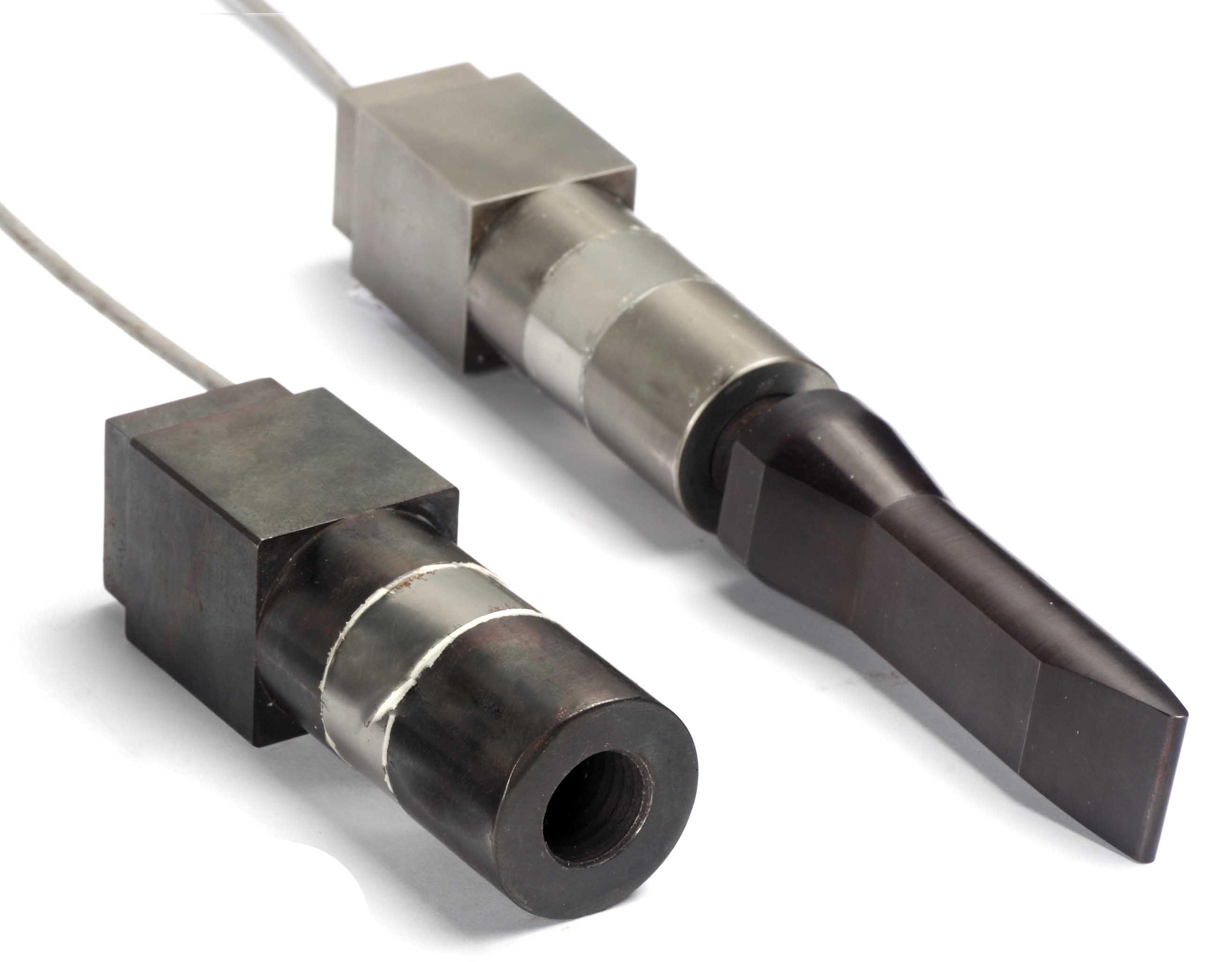

Accessory center

-

Test scheme and case

-

Service support

-

News information

-

Enter the world

-

Contact us